Home Products Insulation System T-MAX

01. Overview

Byucksan T- Max is eco- friendly Polyester Sound Absorption Insulation tile and doesn't expel Vocs, formaldehyde. It is possible to graft to the construct

or industry's market variously(ex. sound-absorbing walls, interior sound absorption finishing material, car interior material, exterior panel etc.). It's the material that can make non-air pollution environment.

Certification

02. Features

- Vocs and formaldehyde are not generated.

- It has superb sound Absorption and insulation.

- It is possible to recycle and to burn.

- It is flame resistant (self-fire extinguishing), no toxic gases are not generated during combustion.

- Drainage and safety of types are superb and it is semi-permanent.

Applications

- Sound absorption and insulation for Walls, ceilings, floors of buildings

- Finishing materials for sound absorption in theaters, conference rooms, lecture halls, gyms, churches, etc.

- Fillers for the lightweight dividers and studs

- Sound absorption sound proof materials for soundproof walls on railways and roads,

- Soundproof and thermal materials in machinery rooms and conditioning rooms

- Apartment's dew condensation Prevention Material / Floor noise damping Material

- Anti-sweating thermal insulation and floor noise reducing materials in apartment buildings

03. Product Category

Variety of Products

| Classification | T-MAX (Soft Type) |

T- Board & Art Board (Hard Type) |

Remark |

| Density (Kg/㎥) | 24 ~ 80 | 80 ~ 400 | Various sizes (dimensions) and colors are available upon your request. |

|---|---|---|---|

| Thickness (mm) | 10 ~ 100 | 5 ~ 25 | |

| Width (mm) | 2,000 | 1,200 | |

| Length (mm) | Order made | 2,400 | |

| Types | Plate/Roll | Plate |

T-MAX

-

- High density polyester sound absorption insulation T-board& Art board

- Product infomration: T-board and Art board are the first interior sound absorption finishing materials of hard board types developed in the world.

- Spec: Density ⇒ 80~400(K) / Thickness ⇒ 5~25(T)

-

- Polyester of embo-type, sound absorption insulation T-max Embo

- Product information: T-max Embo is embo-processed on its upper part and has excellent durability. With expansion of air space in the embo, this product has improved sound absorption, permeability and insulation.

- Spec: Density ⇒ 32~80(K) / Thickness ⇒ 10~100(T)

-

- Dual-type polyester, sound absorption insulation T-max double

- Product information: As for T-max double, low density part has higher adhesiveness and high density part can be used to finish interior design.

This is used as indoor sound absorption finishing materials. - Spec: Density ⇒ 40~80(K) / Thickness ⇒ 10~100(T)

-

- Closing polyester sound absorption insulation T-max net

- Product information: Net patterns are engraved on the surface of T-max double.

This enhances sound absorption and it is possible to finish without the textile backing. - Spec: Density ⇒ 40~80(K) / Thickness ⇒ 10~100(T)

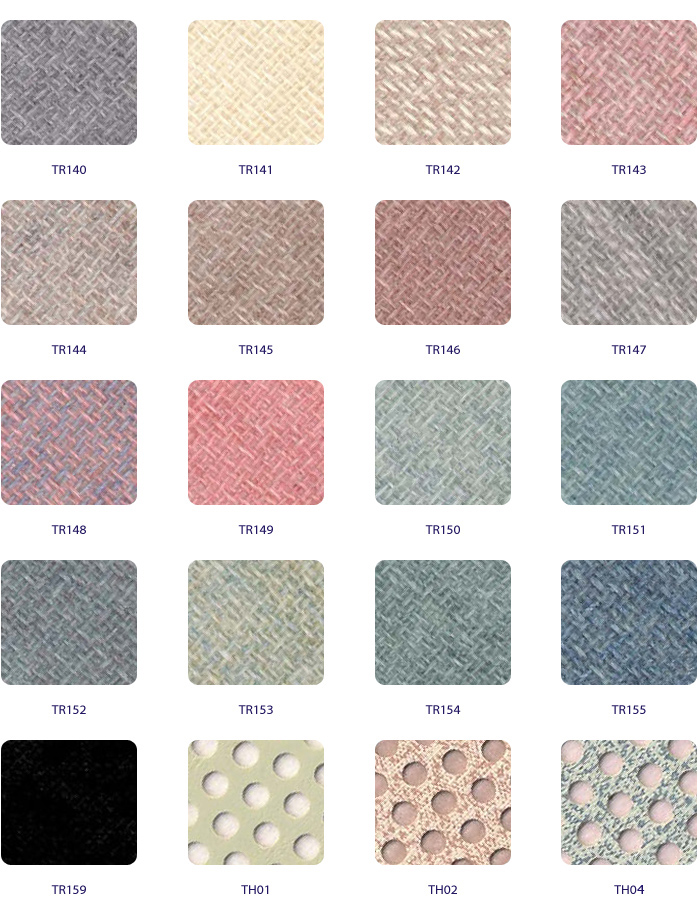

T-Fabric

T- Fabric is interior fabric with flame retardant.

Physical Properties

| Classification | T- MAX (Polyester) | |

| Methods of Production | Thermal Compression Bonding 100% of Polyester (self-melting bond) |

|

|---|---|---|

| Physical Properties |

Materials | Polyester Organic Substance |

| Noise Reduction Coefficient(NRC) |

0.75~0.83 | |

| Thermal Conductivity (W/m · K) |

0.030~0.039 | |

| Density(kg/㎥) | 10~400 | |

| Thickness(mm) | 10~100 | |

| Heat Resistance Temperature(℃) |

~260 | |

Sound Absorption Performance

- Certified Institute: Instititute Certified by KOLAS

- Test results: Sound Absorption Coefficient by Frequency

| HZ | Division | 250 | 500 | 1000 | 2000 | NRC Value |

| T-M4525 | Sound Absorption Material |

0.28 | 0.59 | 0.83 | 0.91 | 0.65 |

| T-M4050 | Sound Absorption Material |

0.80 | 0.93 | 0.80 | 0.77 | 0.83 |

Measurement: KS F 2805 reverberation indoor sound absorption measurement

Performance of Flame - Resistant

- Measurement Method: Enforcement decree related to installation, maintenance and safe management of

Fire Protection System and McCulburner Act - Measured by: FITI Testing & Research Institute, Korea Fire Safety Association

(Korea Fire Equipment Inspection Corporation|)

| Division | Validity (Interior Design Materials) |

Test Result | Remark |

| After Glow Time (sec.) |

within 10 | 0 | Passed |

| After Flame Time (sec.) |

within 30 | 0 | |

| Area of Carbonization (㎠) |

within 50 | 22.5 | |

| Length of Carbonization (㎝) |

within 20 | 7.0 |