-

- Non-flammable and Sound Absorbing Mineral wool Ceiling Tile Available to Install Directly to Steel Support without Shifting Materials, and Economic Feasibility and Design!

-

- Product Inquiry : (+82) 02-2260-6234

- E-mail : zeroeat@bsco.co.kr

- Export Inquiry : (+82) 02-2260-6078

- E-mail : esther711@bsco.co.kr

- Design Inquiry : (+82) 02-2260-6118

- E-mail : ykcho@bsco.co.kr

- Introduction

-

Byucksan Eztone is mineral wool sound absorbing ceiling system available to install directly to steel support.

Unlike the previous construction method, Eztone can reduce material expenses and construction time as installation directly to steel with screw nail or tacker construction method. Also, Byucksan Eztone is unharmful to human body by using mineral wool as the main raw material, and has functions of high sound absorption, non-flammability and simple construction.

Meet Byucksan Eztone for new construction and remodeling schools, offices, commercials, hospitals and others! - Certificates

-

-iloveimg-resized.jpg)

- Application

- School, office, commercial, hospital, hall, etc.

- Features

-

-

Economic Feasibility

Convenient to check back side of

ceiling as directly constructing

on the steel support without gypsum

board shifting materials, and

economical by reducing time and

expenses.

-

Insulation Performance

Energy saving with 3 times higher thermal

resistance than gypsum board,

and create all-time refreshing internal

environment.

-

Sound Absorption

Create quiet and refreshing environment

by controlling internal echo or external

noise as Eztone is formed with mineral

wool that has high sound absorbing

function.

-

Lightness

Convenient in handling with lighter

density of 500kg/㎥ or less, and reduce

weight of building.

-

Eco-Friendliness

Eco-friendly product acquiring

Eco-Friendly Construction Material

Certificate from Korea Air Cleaning

Association.

-

Processability

Easy construction compared to the

previous construction method as

continuous construction is available

with turbo driver or tacker gun.

-

Non-flammability

Excellent fire expansion prevention

in case of internal fire as the

noninflammable ceiling system is

appropriate to the standard of Korean

Industrial Standard KS F ISO 1182

(Non-flammability Test), KS F 2271

(Gas Hazardous Test).

-

Economic Feasibility

- Construction Cases

-

- Eztone Type

-

-

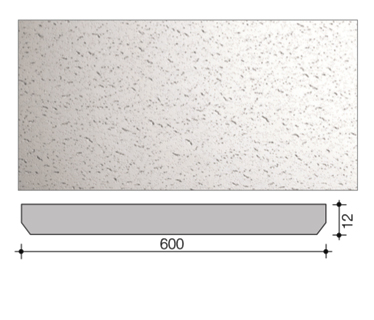

Ez-1200

Size : 12×300×600㎜ (chamfer)Packing : 18 sheets(3.24㎡)/BOX

Size : 12×300×600㎜ (chamfer)Packing : 18 sheets(3.24㎡)/BOX

-

| Item | Unit | Standard by KS L 9105 |

|---|---|---|

| Density | kg/㎥ | 500 or lower |

| Moisture content | % | 3.0 or lower |

| Bending failure load | N | 60 or higher |

| Thermal resistance | ㎡·K/W | 0.19 or higher |

| Average acoustic absorption rate | NRC | 0.41~0.60 |

| Flame retardant level | - | Non-flammability |

| Perpendicularity | - | 1/1000 or less(if cut process the side) |

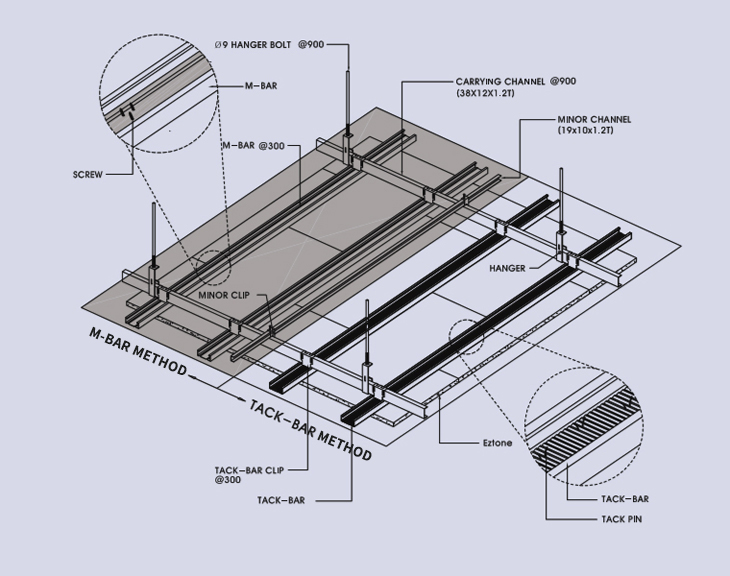

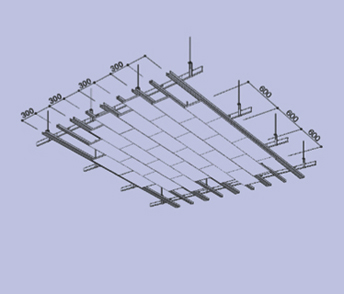

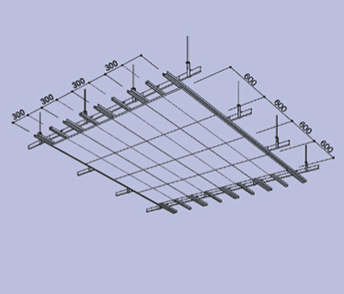

- Eztone Working Drawing

-

-

Eztone Ceiling Structural Drawing

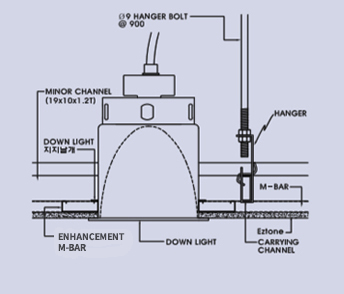

In case of installing down lights after installation of Eztone ceiling, make sure to reinforce with subsidiary M-Bar to prevent sag of ceiling surface by the weight of the lights.Please reinforce other ceiling facilities i.e. speakers, sprinkler head, fire detector, etc. with the same method as above.

In case of installing down lights after installation of Eztone ceiling, make sure to reinforce with subsidiary M-Bar to prevent sag of ceiling surface by the weight of the lights.Please reinforce other ceiling facilities i.e. speakers, sprinkler head, fire detector, etc. with the same method as above.

-

-

-

Down Light Enhancement Detail

-

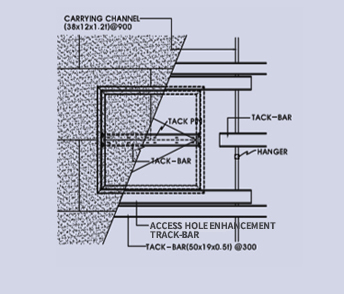

Install access hole (TACK-BAR Method)

-

300×600mm pattern (offset)

-

300×600mm pattern (straight set)

-

- Construction Method

-

1) Preparation

Check smoothness of ceiling surface and dryness of concrete surface at the site, then make sure not to mix dust or impurities.

2) Set Main Line

Measure the site precisely by considering the size of Eztone, then set the main line after considering other procedures i.e. lighting fixture line, diffuser location, etc.

3) Install Strong Anchor

Install strong anchor (Ø9.5) in 900~1200mm space in consideration of installation direction of carrying channel.

4) Check Molding Line Level

Confirm location by drawing, then check point by water level or laser level and process marking.

5) Attach Wall Molding

Fix hanger bolt (rust-proofed Ø9 x 1000mm or more) to strong anchor, then connect hangers.

6) Install Hanger Bolt

Check smoothness of ceiling surface and dryness of concrete surface at the site, then make sure not to mix dust or impurities.

7) Install Curtain Box

Manufacture and install appropriate product according to size and usage.

8) Set Lighting Fixture Line

Set lighting fixture line after an agreement with person in charge of electricity and facility according to specification of lighting fixture.

9) Install Carrying Channel

Settle hanger set and carrying channel in 900~1200mm space, then connect with carrying joints.

10) Install Minor Channel

Install in 2000~3000mm space with clips.

11) Install M-Bar / Tacker Bar

Install M-Bar or tacker bar in 300mm space by using carrying channel and M-Bar clips.

12) Install Eztone

① Readjust level of ceilings, then fit accurately with hanger bolts and nuts.

② Fix Eztone by using screw nails (6ea/sheet : 300×600), or tacker pin (18~20 pins/sheet) depending on M-Bar or tacker bar.

③ Replace or repair damaged surface of Eztone, then process finishing for ceiling.

Ceiling System

Ceiling System Insulation System

Insulation System Interior System

Interior System Exterior System

Exterior System