-

- “Byucksan ENERFree” is High-Efficiency Exterior System which Started New Construction Culture of Insulation and Finishing at the Same Time by Adapting Exterior Wall Insulation Finishing Method for the First Time in Korea.

-

- Product Inquiry : (+82) 02-2260-6054

- E-mail : leehwa5855@bsco.co.kr

- Export Inquiry : (+82) 02-2260-6078

- E-mail : esther711@bsco.co.kr

- Design Inquiry : (+82) 02-2260-6118

- E-mail : ykcho@bsco.co.kr

- Introduction

- Byucksan ENERFree exterior wall insulation finishing method is excellent in economic feasibility, functionality, processability and beauty.

- Certificates

-

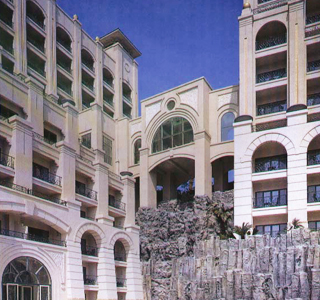

- Application

-

Exterior wall of all buildings where directly/indirectly face outside air

School, commercial, resort, hotel, apartment, outlet, etc. - Features

-

-

Economic Feasibility

• Reduce cooling/heating expenses

by perfect insulation effect

• Cheapest direct construction expenses

among walls

• Maximize practical area and cheap maintenance

expenses

Byucksan ENERFree method does not require extra insulation and waterproof construction, and economical from maintenance/management with minimum expenses from short construction period and maximum insulation effect.

-

Functionality

• Condensation prevention by perfect

insulation/High temperature/humidity

effect

• Outer wall crack prevention,

easy maintenance, waterproof/dampproof

and heat storage effect

Byucksan ENERFree method saved 30% or more energy, and removed defect causes i.e. dew condensation and thermal bridge with perfect waterproof, dampproof, crack prevention.

-

Processability

• Available to construct in four seasons

and use building during construction

• Unnecessary separate finishing and

shorten construction period

• Convenient uneven and curve construction

Available to construct on uneven or curved area with excellent flexibility and processability, shorten construction time with various methods fit to the site as easy/difficult construction is available, and construct the best and optimum building.

-

Beauty

• Express perfect curve and shape

and infinite application

• Various finishing (color, texture)

and harmony with different matters

Convenient processability of insulation plate allows application to any type of building, and various finishing color and texture can fully show the characteristics.

Also, appearance of modern classic sense can be made as harmonizing with molding.

-

Economic Feasibility

- Construction Cases

-

- BYUCKSAN ENERFREE noncombustible Finishing Materials

-

-

- Neovit (silicon)

-

-

Low water absorptiveness

Low water absorptiveness

Excellent washability

Fair vapor permeability

Resistance to bacteria and air pollution

※ Neovit finishing (patented product) type : Neostandard, Neo Sand Finish, Neo Free Finish

stain resistance silicon type finishing improving pollution issue innovatively from the previous finishings

-

- Euro Stucco

-

-

Lotus Pattern

Luxurious finishing creating classical mood

Create various patterns by diverse construction methods

(spray type, roller type, mix type)

Easy construction and excellent workability

※ Luxurious fashion finishing which surpass the limit of finishing expression

-

-

-

Wave Pattern -

Pattern Roller #1 -

Pattern Roller #2

-

- Inno Stucco

-

-

Caribbean Pattern (2-Tone)

Nature-friendly, non-crack soft texture

Spotlighted as luxurious finishing for pure interior

Excellent in construction with solving crack issue and expressing 2-Tone texture

※ Mediterranean nature-friendly finishing

-

-

-

Sandstone Pattern (2-Tone) -

Pattern Roller #1(2-Tone) -

Lotus Pattern (2-Tone)

-

- Standard Finish

(Acrylic) -

-

Prevent contraction with excellent elasticity

Prevent contraction with excellent elasticity

Various Colors

Permanent color maintenance

Construction method: With trowel for finishing

※ Most commonly used as a general finishing material of outside insulation finishing

-

- Sand Finish

(Acrylic) -

-

Stable texture expression with consistent particle size (1.2mm particle)

Stable texture expression with consistent particle size (1.2mm particle)

Prevent contraction with excellent elasticity

Permanent color maintenance (create UV ray block)

Construction method: With trowel or spray for finishing

※ Stable textured finishing with consistent particle size

-

- Free Finish

(Acrylic) -

-

Express soft texture with small and fine particles (0.6mm particle)

Express soft texture with small and fine particles (0.6mm particle)

Suitable for EPS molding curved surface, etc.

Prevent contraction with excellent elasticity

Construction method: With trowel or spray for finishing

※ Finishing expressing soft surface with small and fine particles

-

- Stone Series

(Acrylic) -

-

Luxurious finishing expressing with dignified and elegant stone texture

Luxurious finishing expressing with dignified and elegant stone texture

Light finishing which overcome burden of building weight that general stone has Excellent durability and luxurious texture

Construction method: With trowel or spray for finishing

-

- NeoStone - Light

-

Product Name Construction Method Features/Advantages NeoStone - Light

(NSL)Rendering Type(NSL-T)

Spray Type(NSL-S)Seem more like actual stone by using bright natural stone Color & Texture Rendering Type

(NSL-T)

NSL-T701

NSL-T702

NSL-T703

NSL-T704

NSL-T705

NSL-T706

NSL-T707

NSL-T708

NSL-T709

NSL-T710

NSL-T711

NSL-T712Spray Type

(NSL-S)

NSL-S701

NSL-S702

NSL-S703

NSL-S704

NSL-S705

NSL-S706

- Zenith

-

Product Name Construction Method Features/Advantages Zenith

(GST)Rendering Type (GST) Luxurious texture stone finishing with textured particle Color & Texture Rendering Type

GST-001

GST-002

GST-003

GST-004

GST-005

GST-006

GST-007

GST-008

- NeoStone - Luxe

-

Product Name Construction Method Features/Advantages NeoStone - Luxe

(NSX)Spray Type(NSX-S)

(Separately mix chip during construction)Expressed feeling of actual stone by improving feeling of stone by adding various colors of color chips Color & Texture Spray Type

(NSX-S)

NSX-S801

NSX-S810

NSX-S804

NSX-S812

NSX-S806

NSX-S814

NSX-S808

NSX-S815Spray Type

(CHIP)

White

Light Grey

Dark Grey

Black

Yellow

Brown

Rust

Dark Brown

- NeoStone -

Luxe Prime -

Product Name Construction Method Features/Advantages NeoStone

Luxe Prime

(NSX-P)Spray Type (NSX-P)

(Separately mix chip during construction)Expressed feeling of actual stone by improving feeling of stone by adding various colors of color chips Color & Texture Standard

P1(White)

P2(Grey)

P3(Khaki)

P4(Brown)

P5(Red)

P6(Black)

P7(Pure Black)

P8(Dark Black)

P9(Dark Red)Spray Type

(NSX-P)

NSX-P802(P1, P2)

NSX-P807(P9, P6, P2)

NSX-P805(P6, P4, P1)

NSX-P806(P8, P3)

- NeoStone - MILD

-

Product Name Construction Method Features/Advantages NeoStone - MILD

(MILD)Spray Type Aqueous type eco-friendly in/exterior finishing creating elegant pattern Color & Texture Spray Type

(NSX-S)

Grey

Red

Dark Grey

Light Brown

Black

Light Red

Light Grey

White

- New Adhesives

-

-

Isopink Adhesive

Prevent external crack with excellent elasticity

Anti-bacteria and excellent contamination prevention

Excellent waterproof with high molecular resin

-

EDT Adhesive

(Enerfree Dual Track

Base Coat)Non Cementitious Base Coat

Adhesive with main raw material of aqueous acryl without Portland cement

Excellent flexibility and surface crack resistance

Prevent whitening issue compared to the previous adhesives

-

Isopink Adhesive

- Recoating

-

-

Unlike general paints, no surface occurs (excellent adhesiveness)

Maintain previous surface texture

Various color expression and easy construction

※ Recoating paints manufactured by special technology of Byucksan, used for contaminated exterior wall insulation area and color change

-

- Neo Recoating

-

-

Excellent washability

Block aqueous and oily stain

Strengthen contamination resistance as non-toxic

Excellent workability and fast dry

※ Fluorinated recoating applied widely without property limit of the previous coating

-

- Molding Top

-

-

Strengthen surface strength of EPS molding and improve durability

Replacement of reinforcing mesh of complex EPS molding

Excellent workability (shorten construction period, reduce expenses)

Reduce distortion rate of EPS molding

-

- Neo Clear Sealer

-

-

Fluorinated sealer used above general finishing

Strengthen contamination resistance as non-toxic

Construction method: With roller or spray

※ Maintain appearance of building clean for a long time as fluorinated chemical

-

- Base Primer

-

-

Treat base surface before construction

Improve adhesiveness of insulation system

※ Surface treatment applied to background while attaching EPS Board for outside insulation as primer for in/external use

-

- Neo Flex

-

-

Prevent external crack with excellent elasticity

Anti-bacteria and excellent contamination prevention

Excellent waterproof with high molecular resin

※ Prevent external crack of building, and best elasticity finishing for building protection and contamination prevention

-

- ENER Free Standard Color

-

201 SUPER WHITE

201 SUPER WHITE 202 BRITE WHITE

202 BRITE WHITE 203 NATURAL WHITE

203 NATURAL WHITE 204 DOVER SKY

204 DOVER SKY 208 MANOR WHITE

208 MANOR WHITE 210 VAN DYKE

210 VAN DYKE 213 AMARILLO WHITE

213 AMARILLO WHITE 209 EGGSHELL CREAM

209 EGGSHELL CREAM 212 SANDLEWOOD BEIGE

212 SANDLEWOOD BEIGE 217 COLONIAL TAN

217 COLONIAL TAN 207 SUNSET YELLOW

207 SUNSET YELLOW 255 MIMOSA YELLOW

255 MIMOSA YELLOW 256 ASPEN YELLOW

256 ASPEN YELLOW 251 BRIGHT SUN

251 BRIGHT SUN 253 GOLDEN YELLOW

253 GOLDEN YELLOW 231 GULL GREY

231 GULL GREY 205 SUEDE

205 SUEDE 211 PRAIRIE GREY

211 PRAIRIE GREY 206 PEARL ASH

206 PEARL ASH 243 BURLAP

243 BURLAP 215 BEACH

215 BEACH 214 MAUVE

214 MAUVE 216 VICTORIAN LACE

216 VICTORIAN LACE 252 SPANISH YELLOW

252 SPANISH YELLOW 254 GOLDEN BUFF

254 GOLDEN BUFF 219 SALMON

219 SALMON 220 ROSE

220 ROSE 222 PINK SHADOW

222 PINK SHADOW 239 ADOBE ACCENT

239 ADOBE ACCENT 218 CAMEL BACK

218 CAMEL BACK 237 MUSHROOM

237 MUSHROOM 240 TUMBLE WEED

240 TUMBLE WEED 242 SPECTRUM BROWN

242 SPECTRUM BROWN 241 SANDY TAUPE

241 SANDY TAUPE 244 PINECONE

244 PINECONE 232 MOUNTAIN FOG

232 MOUNTAIN FOG 233 DRIFTWOOD

233 DRIFTWOOD 229 SILVER SHADOW

229 SILVER SHADOW 236 SLATE

236 SLATE 245 FOREST EVE

245 FOREST EVE 227 NEWPORT MIST

227 NEWPORT MIST 234 STEEL GREY

234 STEEL GREY 230 GREY FOG

230 GREY FOG 238 MISTY MAUVE

238 MISTY MAUVE 235 FEATHER GREY

235 FEATHER GREY 225 STAR LIGHT

225 STAR LIGHT 226 FROSTY BLUE

226 FROSTY BLUE 228 WEDGEWOOD

228 WEDGEWOOD 262 HONEY BIRD

262 HONEY BIRD 246 JADE

246 JADE 257 LIGHT GREEN

257 LIGHT GREEN 258 PASTEL GREEN

258 PASTEL GREEN 259 OLIVE GREEN

259 OLIVE GREEN 260 IRISH GREEN

260 IRISH GREEN 261 EVER GREEN

261 EVER GREEN 263 SKY BLUE

263 SKY BLUE 264 LIGHT BLUE

264 LIGHT BLUE 265 LADY BLUE

265 LADY BLUE 266 DARK BLUE

266 DARK BLUE 250 SMOKEY BLUE

250 SMOKEY BLUE 267 PINK ANGEL

267 PINK ANGEL 268 PINK LADY

268 PINK LADY 272 LIGHT VIOLET

272 LIGHT VIOLET 273 VELVET

273 VELVET 274 CONCORD

274 CONCORD 221 SUMMER ROSE

221 SUMMER ROSE 269 PINK SWEET

269 PINK SWEET 224 ROSE PETAL

224 ROSE PETAL 270 ALOHA RED

270 ALOHA RED 271 PASTEL RED

271 PASTEL RED 223 SPANISH TILE

223 SPANISH TILE 248 RUSTIC RED

248 RUSTIC RED 247 RED ROCK

247 RED ROCK 249 BARK

249 BARK 275 DARK BLACK

275 DARK BLACK

- Non-combustible Finishing materials

-

Test Item Unit Test Results Note Stability at low temperature - Pass KS F 4715 Resistance for cracking with initial drying - Pass Adhesive strength(Standard) N/㎟ 1.1 Adhesive strength(After immersion) N/㎟ 0.5 Resistance for old and hot cycle(Appearance) - Pass Resistance for cold and hot cycle(Adhesive strength) N/㎟ 0.5 Water absorption coefficient kg/(㎡h0.5) 0.03 Washing resistance - Pass Impact resistance - Pass Alkali resistance - Pass Weather resistance(Appearance) - Pass Weather resistance(Discoloration) Grade 4 Water vapor permeability m 0.8

- Adhesive

-

Test Item Unit Test Method Test Result Year Change % KS F 4716 5 Adhesion Strength - Standard Curing N/㎟ 1.8 Adhesion Strength - Low Temperature Curing N/㎟ 1.4 Fine Crack Resistance - N/A Impact Resistance - N/A Water Absorption Coefficient kg/(㎡h1/2) 0.07 Hot-Cold Successive Resistance - Exterior - N/A Hot-Cold Successive Resistance - Adhesion Strength N/㎟ 1.5 Moisture Permeability (sd) m 0.9

- Standard Finish

-

Test Item Unit Test Method Test Result Low-Temperature Stability - KS F 4715 N/A Fine Crack Resistance by Early Drying - N/A Adhesion Strength - Standard Curing N/㎟ 1.3 Adhesion Strength – After Soaked N/㎟ 0.8 Hot-Cold Successive Resistance - Exterior - N/A Hot-Cold Successive Resistance - Adhesion Strength N/㎟ 0.8 Water Absorption Coefficient kg/(㎡h1/2) 0.07 Washability - N/A Impact Resistance - N/A Alkali Resistance - N/A Moisture Permeability (sd) m 1.2 Weather Resistance - Exterior - N/A Weather Resistance - Discoloration No. 4-5

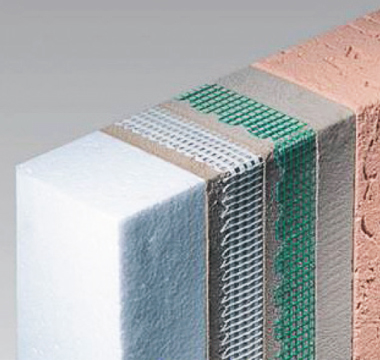

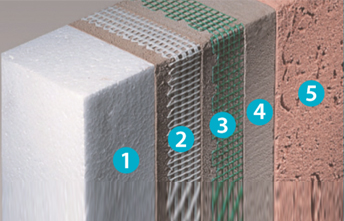

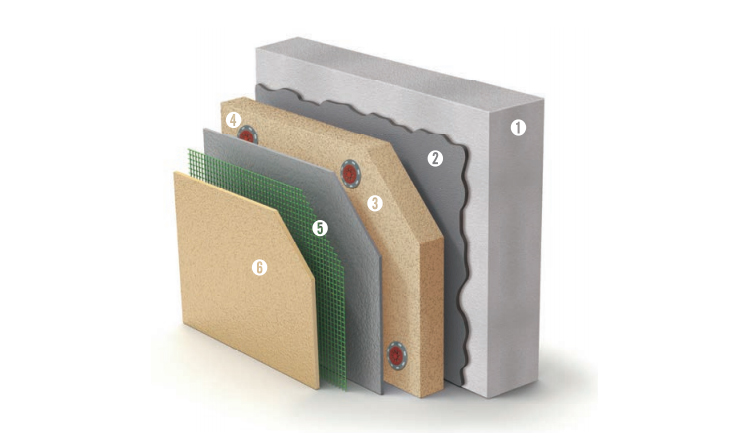

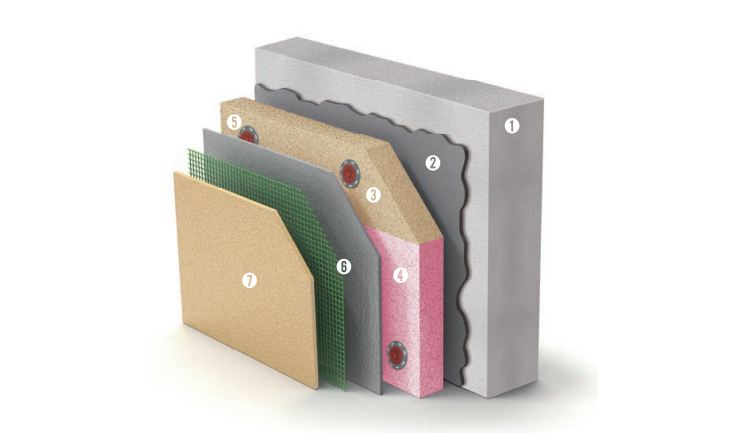

- Composition

-

-

Total System (Wet Construction System)

① E.P.S insulation② High-strength fiberglass (G.L + 1.5m optional)③ Standard fiberglass④ Adhesive⑤ Finishing materials

① E.P.S insulation② High-strength fiberglass (G.L + 1.5m optional)③ Standard fiberglass④ Adhesive⑤ Finishing materials -

Panel System (Dry Construction System)

① METAL STUD② CRC Board (6mm)

① METAL STUD② CRC Board (6mm)

(Cellulose fiber Reinforced Cement Board)

-

-

01. Insulation Plate (EPS, XPS)

Available to use insulation system with appropriate specification according to insulation effect and functions as basic material for exterior wall insulation, and removed potential defect generating elements after construction such as deformation or distortion of insulation plate with strict quality control of Byucksan.

* EPS (Expanded Polystyrene Insulation ) - Organic insulation system recognized by RADCO, USA, and aged for 6 weeks to prevent distortion

* XPS (Extruded Polystyrene Insulation, Isopink) - Organic insulation system with low thermal conductivity, lowest vapor permeance among insulation systems, and self fire-extinguishing capability

02. Adhesive

Basic material for exterior wall insulation system attachment and mesh impregnation, must use adhesive complying with with specification according to type of insulation system, and manufactured by raw materials of Byucksan’s special specification.

* Adhesive for EPS - Use by mixing cement with ratio fit to specification, and use during insulation system attachment and mesh impregnation.

* Adhesive for XPS - XPS exclusive adhesive made by special binder and special filler to be suitable to insulation board with low moisture absorptiveness, and using principle to mix fluid and powder immediately on site.

03. Fiberglass Mesh (MESH)

Mesh with strong tensile strength made by 100% fiberglass with crack prevention and impact resistance functions, and classified as 1) Standard Mesh 2) Impact Reinforcement Mesh 3) Super Strong Reinforcement Mesh depending on its usage.

* Crack prevention and impact reinforcement

* Durability enhancement (alkali resistance coating treatment) and self fire extinguishing capability granted empowerment

04. Finishing Materials

Manufactured by synthetic of special acrylic resin and selected various additives and special silica, and finishing material with various textures with weather resistance and durability but no discoloration. Especially, Neovit is a silicon finishing which improved pollution issue innovatively.

*Luxurious various colors and textures applicable to in/outside

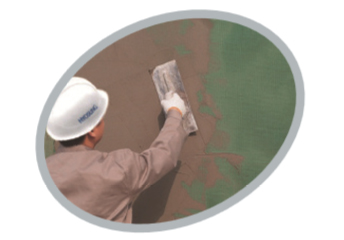

- Construction at Site

-

-

01. Mix adhesive and general cement according to specification, and tightly attach insulation plate to background with block stacking method.

01. Mix adhesive and general cement according to specification, and tightly attach insulation plate to background with block stacking method. -

02. Apply mixed adhesive mortar thinly to EPS insulation plate surface thinly, then apply adhesive mortar again as fiberglass mesh does not expose as it impregnate fiberglass.

02. Apply mixed adhesive mortar thinly to EPS insulation plate surface thinly, then apply adhesive mortar again as fiberglass mesh does not expose as it impregnate fiberglass. -

03. Adhesive finishing materials of desirable color to surface of cured adhesive mortar layer.

03. Adhesive finishing materials of desirable color to surface of cured adhesive mortar layer. -

04. Create finishing pattern depending on chosen texture.

04. Create finishing pattern depending on chosen texture.

-

- Remodeling Method ※ Remodeling process of Ulsan University Hospital

-

-

01. Arrange tilesArrange tiles which may fall by high pressure washer.

01. Arrange tilesArrange tiles which may fall by high pressure washer. -

02. Attach EPS board.

02. Attach EPS board. -

03. Reinforce FastnerPrevent falling of insulation by fixing hardware (fastener) for dryvit on insulation plate

03. Reinforce FastnerPrevent falling of insulation by fixing hardware (fastener) for dryvit on insulation plate -

04. Wind MeshWind green standard mesh on surface to prevent crack, and if necessary, construct white reinforcement mesh to bottom 1.5m in priority to prevent damage from impact.

04. Wind MeshWind green standard mesh on surface to prevent crack, and if necessary, construct white reinforcement mesh to bottom 1.5m in priority to prevent damage from impact. -

05. Apply finishing materialsConstruct finishing materials of desired color and texture.

05. Apply finishing materialsConstruct finishing materials of desired color and texture. -

06. Completion

06. Completion

-

- Construction order

-

-

01.Concrete framework

01.Concrete framework -

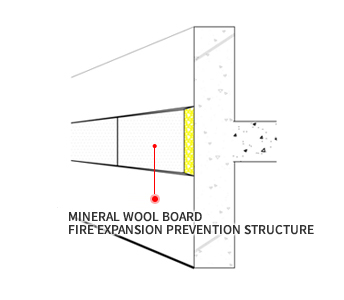

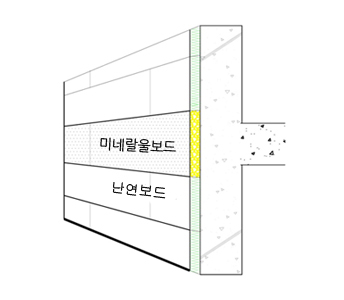

02.Attach M/W board - Fire expansion preventing structure

02.Attach M/W board - Fire expansion preventing structure -

03.Attach bead method insulating materials

03.Attach bead method insulating materials -

04.Construct mesh, adhesive, finishing materials

04.Construct mesh, adhesive, finishing materials

-

- Construction Details

-

-

- Introduction

-

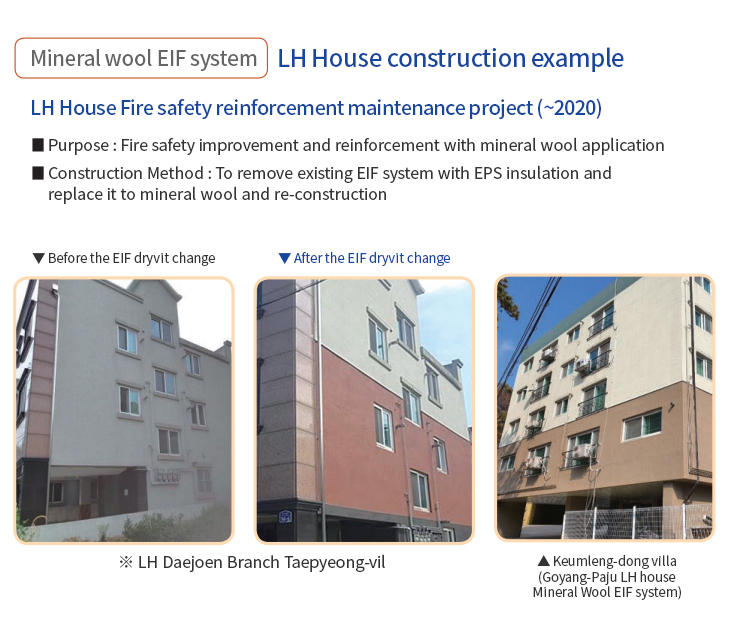

The most perfect non-combustible EIF system for fire safety

- Advantages

-

Fire safety Non-combustible EIF system with the best existing non-combustible insulation mineral wool Workability Excellent to shorten the construction time with simultaneous insulation and finishing Aesthetics Flexible coordination with various finishes (colors, textures) and other materials

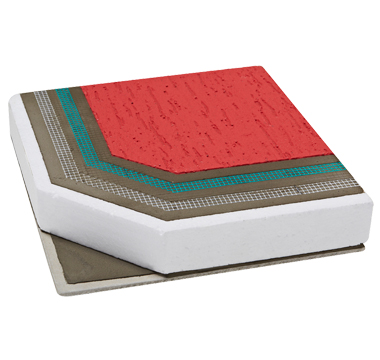

- NON-COMBUSTIBLE

ENERFREE MINERAL WOOL

TOTAL SYSTEM -

-

① Structure② Adhesive③ Mineral wool board for EIFs (Density with 100㎏/㎡↑)④ Fastener for Mineral wool⑤ Standard Mesh⑥ Non-combustible Finishing

① Structure② Adhesive③ Mineral wool board for EIFs (Density with 100㎏/㎡↑)④ Fastener for Mineral wool⑤ Standard Mesh⑥ Non-combustible Finishing

-

- ENERFREE MINERAL WOOL FIRE STOP SYSTEM

-

-

① Structure② Adhesive③ Mineral wool board for EIFs (Density with 100㎏/㎡↑, Thickness with 50mm↑, Width of each floor at least 400mm)④ Insulation⑤ Fastener for Mineral wool⑥ Standard Mesh⑦ Non-combustible Finishing

① Structure② Adhesive③ Mineral wool board for EIFs (Density with 100㎏/㎡↑, Thickness with 50mm↑, Width of each floor at least 400mm)④ Insulation⑤ Fastener for Mineral wool⑥ Standard Mesh⑦ Non-combustible Finishing

-

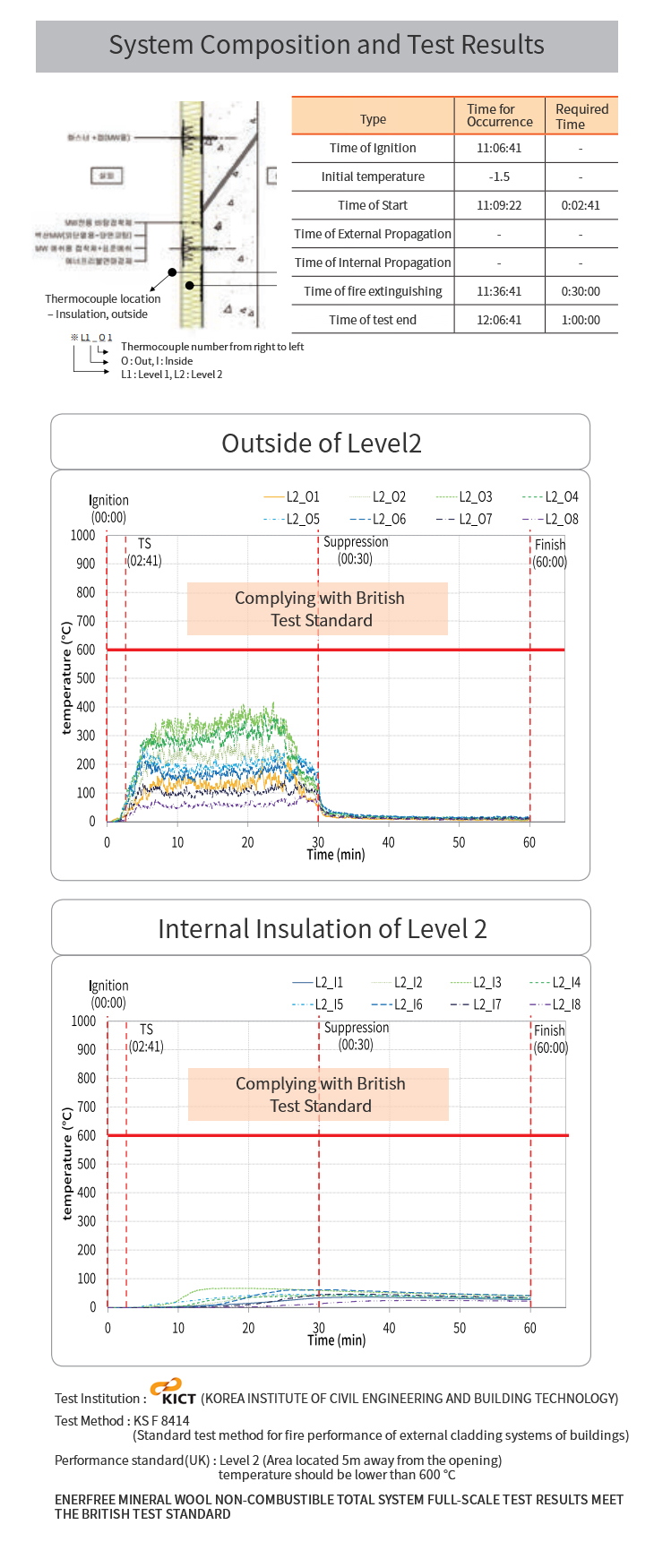

- Full-scale System Test Result

-

- Reference

-

- Installation

-

-

1. Remove the existing insulation and apply surface reinforcement primer

1. Remove the existing insulation and apply surface reinforcement primer -

2. Apply surface reinforcement on mineral wool and put mineral wool adhesive.

2. Apply surface reinforcement on mineral wool and put mineral wool adhesive. -

3. Install mineral wool insulation

3. Install mineral wool insulation -

4. Apply surface reinforcement on mineral wool insulation

4. Apply surface reinforcement on mineral wool insulation -

5. Install fasteners for mineral wool

5. Install fasteners for mineral wool -

6. Render for mineral wool

6. Render for mineral wool -

7. Apply normal(standard) Mesh

7. Apply normal(standard) Mesh -

8. Apply finishing material

8. Apply finishing material

-

- TEST REPORT

-

Ceiling System

Ceiling System Insulation System

Insulation System Interior System

Interior System Exterior System

Exterior System