-

-

Lowest Thermal Conductivity among KS Organic Insulation System

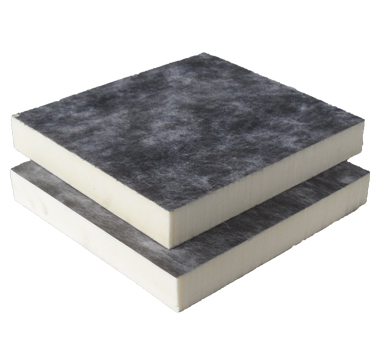

Rigid Polyurethane Foam Insulation System -

- Product Inquiry : (+82) 02-2260-6186

- E-mail : a2230540@bsco.co.kr

- Export Inquiry : (+82) 02-2260-6078

- E-mail : esther711@bsco.co.kr

- Design Inquiry : (+82) 02-2260-6263

- E-mail : grkim@bsco.co.kr

- Introduction

-

Flexible application of insulation system is required as energy saving becomes an issue of the world, insulation regulation from construction law gets strengthened.

Tech Board can supplement insulation feasibility anywhere with better thermal conductivity compared to other commercial construction insulating materials. - Certificates

-

- Application

-

Construction area : Insulating material to ceiling, wall, floor, etc. of all buildings

Other areas : Insulating material to automobile, vessel, freezing/cooling storage, etc. - Features

-

-

Excellent Insulation

Excellent in space applicability as using

thinner board is available compared to

other organic/inorganic insulation System

with the lowest thermal conductivity

(KS M 3809 standard 0.023W/m•K or less)

among commercialized construction

insulating materials.

-

Sound Insulation

Provide cozy residence by blocking

internal/external noises of building.

-

Various Choice of Surface Finishing

Available to apply various surface

finishing from production process.

(non-woven fabric, foil, etc.)

-

Eco-Friendliness

Eco-friendly material without organic

compound (TVOC, HCHO-formaldehyde,

benzene, etc.) which acquired

eco-label certification, healthy building

material.

-

Excellent Insulation

- Type

-

Type Description Characteristics Insulation Plate Type 1 No.1 Plate shaped insulation without foamed surface material with raw materials of polyisocyanate, polyol and blowing agent High density No.2 Mid density No.3 Low density Insulation Plate Type 2 No.1 Plate shaped insulation attaching surface material formed in sandwich shape by self-adhesion by blowing between surface materials with raw materials of polyisocyanate, polyol and blowing agent High density No.2 Mid density No.3 Low density - Size

-

(Unit : mm)

Type 20 ~ 45 50 ~ 120 125 or higher Thickness Tolerance ±2 ±3 Followed by agreement Width Tolerance 1,000 ± 5 Length Tolerance 1,800 ~ 3,100 ± 5 (by each 10mm) ※ 1.Standard size : Thickness X Width X Length = Thickness X 1000 X 2000

※ 2.Size of the ordered goods may be defined by the agreement between people in charge of undertake/delivery. The tolerance at the time shall be followed by the table above.

| Type | Apparent Density (kg/㎥) | Thermal Conductivity (W/m·K) | Bending Strength (N.㎠) | Compressive Strength (N/㎠) | Absorption Amount (g/100㎠) |

Combustibility | |

|---|---|---|---|---|---|---|---|

| Insulation Plate Type 1 | No.1 | 45 or higher | 0.024 or lower | 35 or higher | 30 or higher | 3.0 or lower | Combustion time shall be within 120 seconds, and the combustion length shall be 60mm or less. |

| No.2 | 35 or higher | 0.024 or lower | 25 or higher | 20 or higher | |||

| No.3 | 25 or higher | 0.025 or lower | 15 or higher | 10 or higher | |||

| Insulation Plate Type 2 | No.1 | 45 or higher | 0.023 or lower | 35 or higher | 15 or higher | 3.0 이하 | - |

| No.2 | 35 or higher | 0.023 or lower | 25 or higher | 10 or higher | |||

| No.3 | 25 or higher | 0.024 or lower | 15 or higher | 8 or higher | |||

- Construction Order and Application

Ceiling System

Ceiling System Insulation System

Insulation System Interior System

Interior System Exterior System

Exterior System