-

- Heating Insulation System Usable in Various Ways for Construction, Industry, Ship

-

- Product Inquiry : (+82) 02-2260-6242

- E-mail : bsyoung@bsco.co.kr

(For Industrial Use)- (+82) 055-367-7880

- jcj815@bsco.co.kr(For Shipbuilding Use)

- Export Inquiry : (+82) 02-2260-6078

- E-mail : esther711@bsco.co.kr

- Design Inquiry : (+82) 02-2260-6263

- E-mail : grkim@bsco.co.kr

- Introduction

- Byucksan Mineral Wool has very wide range of use compared to the other insulations as made by hot-dip calcium silicate ore with high temperature. It is used for from fireproof/sound absorption/heating/insulation of buildings to heating/insulation/cooling of various plants, ships, and seed plate for agriculture. Also, it is essential material for energy saving with flexible fiber, excellent recovery and low thermal conductivity compared to other products.

- Certificates

-

- Application

-

Maintenance facility, sanitary arrangements, condensation prevention, rooftop insulation, outer wall insulation, cold storage, etc.

Thermal material of ship, boiler furnace wall, piping, drying furnace, heat treatment equipment, etc.

Sound facility of hall, building, machinery room, electricity room, office, gym, sound proof panel, various plant sound proof construction, various partition, etc.

Various fireproof structural method materials, fireproof partition core materials, fireproof door core material

- Features

-

-

Heat Insulation

Byucksan Mineral Wool with consistent

and fine 5μ fiber shows excellent

heating/insulation effect with low thermal

conductivity.

-

Sound Absorption

Excellent sound absorption with high

density, air thickly placed between thin

fiber, and show great effect from low

frequency which is difficult to absorb.

Also, great sound insulation can be

expected if filled inside the partition wall.

-

Non-flammability

Used for fireproof structure with high

thermal resistance as artificial mineral

fiber.

-

Processability

Not easily damaged with abundant

flexibility as fiber material, easy to

cut with cutter.

-

Humidity/Weather Resistance

Not absorbing humidity in air,

stabilize tissue, and excellent in

weather resistance compared to

other insulations

-

Heat Insulation

- Felt FELT

-

※ Actual product may seem different vary from the image, please contact the sales staff for the details.

※ Actual product may seem different vary from the image, please contact the sales staff for the details.

-

Byucksan Mineral Wool heat insulating board is the processed product in a board with adhesive binder, has features of light, elasticity, excellent sound absorption/sound insulation/insulation and humidity resistance.

- Features

-

- Economical, excellent in insulation and heating effects.

- Excellent in sound absorption and sound insulation.

- Excellent in elasticity.

- Application

-

- Apartments, insulation/condensation prevention of general houses

- Sound proof of school, general houses

- Insulation of duct/sound absorption of machinery and electricity rooms

- Insulation/Sound absorption of wall/partition

- Sound absorption materials for sound adjustment of hall, studio, gym, etc.

- Fireproof zone

- General Size and Properties

-

Density

(kg/㎡)Standard Size Thermal Conductivity W/mK Heat Shrinking

Temp. (℃)Thickness

(mm)Width

(m)Length

(m)Average Temperature 70℃

{Average Temperature 20℃}50 50 0.5 1 0.049

{0.039} or lower400 or higher 60 ※ Properties Standard : KS L 9102.

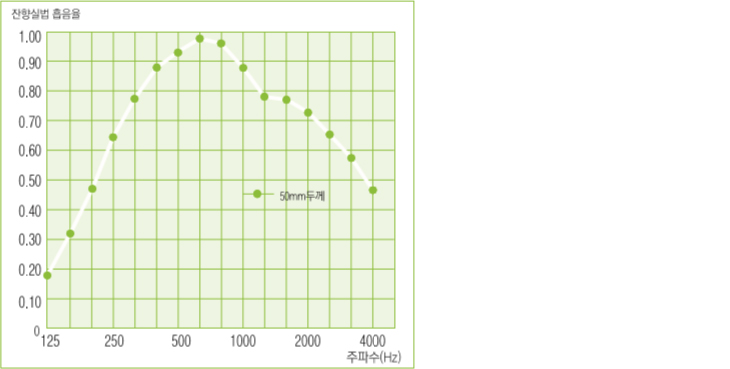

- Reverberant Sound Absorption Coefficient

-

Mineral Wool Felt (Air Layer 0mm) Air Layer 125 250 500 1000 2000 4000 Thickness : 50mm 0.19 0.67 0.94 0.90 0.79 0.48 -

- BLANKET

-

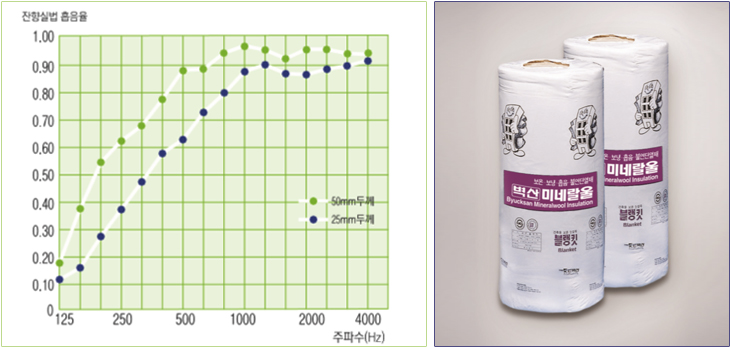

※ Actual product may seem different from the image, please contact the sales staff for the details.

※ Actual product may seem different from the image, please contact the sales staff for the details.

-

Blanket minimizes binder but is reinforced one side with paper or net, and used as heating insulation material of ceiling or round duct of general building.

- Features

-

- Excellent in flexibility.

- Easy to construct for curved or complex construction surface.

- Easy to construct from for curved or complex construction surface.

-

- Ceiling of general building, heating insulation material under floor

- Heating/Insulation/Cooling of various tanks or round ducts

- General Size and Properties

-

Density

(kg/㎥)Standard Size Thermal Conductivity W/mK Heat Shrinking Temp. (℃) Thickness

(mm)Width

(m)Length

(m)Average Temperature 70℃

{Average Temperature 20℃}60 50 1 5 0.049

{0.039} or lower400 or higher 80 25 10 0.044

{0.037} or lower600 or higher 50 5 75 3 ※ Properties Standard : KS L 9102.

- Reverberant Sound Absorption Coefficient

-

Blanket Air Layer (0mm) Frequency (Hz) 125 250 500 1000 2000 4000 Thickness : 25mm 0.11 0.37 0.64 0.87 0.87 0.92 Thickness : 50mm 0.15 0.62 0.89 0.97 0.95 0.95 -

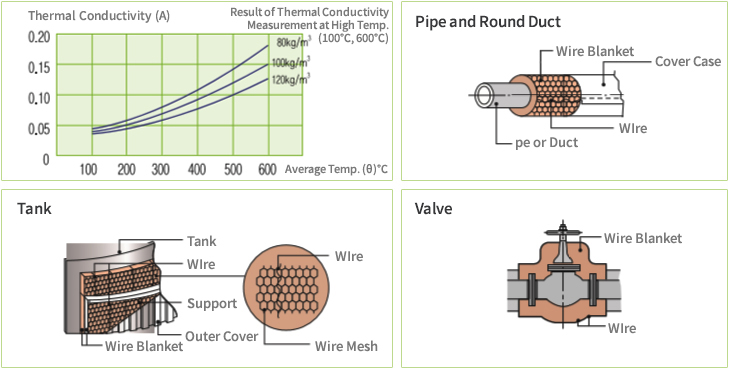

- WIRE BLANKET

-

※ Actual product may seem different from the image, please contact the sales staff for the details.

※ Actual product may seem different from the image, please contact the sales staff for the details.

-

Wired Blanket forms mineral wool into slight amount of binder and make as board, then saw hexagonal wire mesh with galvanized wire on the other side. Excellent in Processability, appropriate to complex curved residual heat construction, and reinforced heat resistance even more as binder is less.

- Features

-

- Excellent Processability.

- Convenient in insulation construction i.e. complex curved surface

- Excellent heat resistance.

- Application

-

- Round duct, large diameter pipe, valve, flange, various tanks, thermal power generating boiler, etc.

- General Size and Properties

-

Density

(kg/㎥)Standard Size Thermal Conductivity W/mK Heat Shrinking Temp. (℃) Thickness

(mm)Width

(m)Length

(m)Average Temperature 70℃

{Average Temperature 20℃}80

10025, 50, 75 1 3

5

100.044

{0.037} or lower600 or higher 120 50 0.043

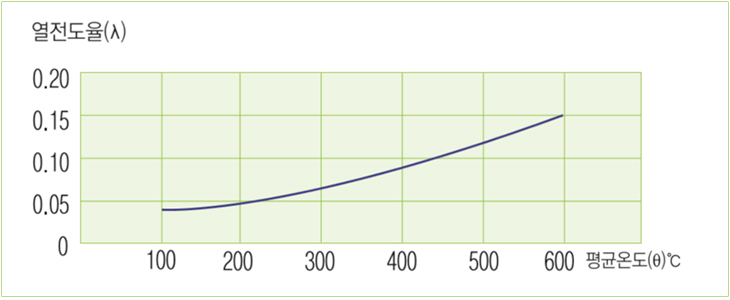

{0.036} or lower600 or higher ※ Properties Standard : KS L 9102. - Thermal Conductivity Reference

-

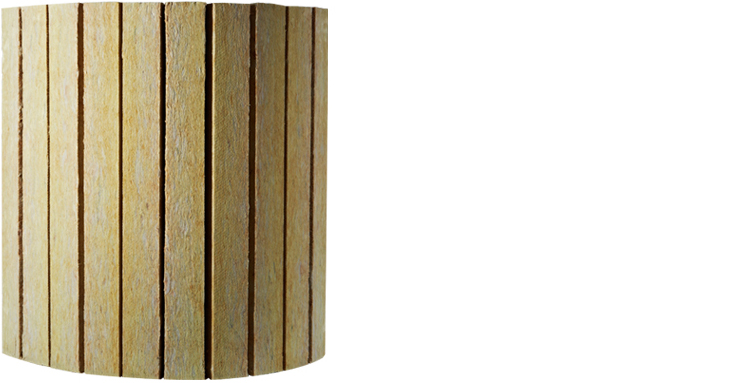

- LAMELA MAT

-

※ Actual product may seem different from the image, please contact the sales staff for the details.

※ Actual product may seem different from the image, please contact the sales staff for the details.

-

Lamela Mat is a product attaching foil by cutting mineral wool heat insulating board into a certain space and stand them in longitudinal fiber direction, and is widely use to round duct and pipe constructions.

- Features

-

- Appropriate for heat/insulation of big-size pipes and round tanks.

- Excellent compressive strength.

- Easy construction.

- additional stiffener required.

- Application

-

- Maintenance, sanitary arrangements (round duct, pipe, curved area, etc.)

- Ventilating duct of apartment kitchen range

- Heating/Sound proof of plant piping, etc.

- fireproof method of pipe for bridges

- General Size and Properties

-

Density

(kg/㎥)Standard Size Thermal Conductivity W/mK Heat Shrinking Temp. (℃) Thickness

(mm)Width

(m)Length

(m)Average Temperature 70℃

{Average Temperature 20℃}80

10050, 75, 100 1 1 0.052

{0.040} or lower600 or higher -

- PIPE COVER

-

※ Actual product may seem different from the image, please contact the sales staff for the details.

※ Actual product may seem different from the image, please contact the sales staff for the details.

-

Mineral Wool Pipe Cover had forming process of making mineral wool into cylindrical shape, and has insulation performance, heat/humidity resistance, processability and flexibility.

- Features

-

- Easy construction.

- 경Light but excellent in insulation/heating.

- Application

-

- Maintenance, sanitary arrangements, heating/insulation of piping

- Heating/Insulation of water pipe

- Fireproof zone, etc.

- General Size and Properties

-

Density

(kg/㎥)Thermal Conductivity W/mK Heat Shrinking Temp. (℃) Average Temperature 70℃

{Average Temperature 20℃}100 ~ 150 0.044

{0.036} or lower600 or higher ※ Properties Standard : KS L 9102. - Thermal Conductivity Reference

-

※ Result of Thermal Conductivity Measurement at High Temp. (100℃, 600℃)

※ Result of Thermal Conductivity Measurement at High Temp. (100℃, 600℃)

- Product Size

-

Pipe Cover Size Pipe Cover Inner Diameter

(mm)Thickness (mm) A B 30 40 50 65 75~150 15 1/2 22 O O O O O 20 3/4 27 O O O O O 25 1 34 O O O O O 32 1 1/4 43 O O O O O 40 1 1/2 49 O O O O O 50 2 61 O O O O O 65 2 1/2 76 O O O O O 80 3 89 O O O O O 100 4 114 O O O O O 125 5 140 O O O O O 150 6 165 O O O O O 200 8 216 X O O O O 250 10 267 X O O O O 300 12 319 X O O O O 350 14 356 X O O O O 400 16 406 X O O O O 450 18 457 X O O O O 500 20 508 X O O O O (Length 1000mm)

※ Available to produce products of 500 ~ 800mm, please contact the person in charge for the order.

Product size is 30~150mm, and available to produce in 5mm unit.

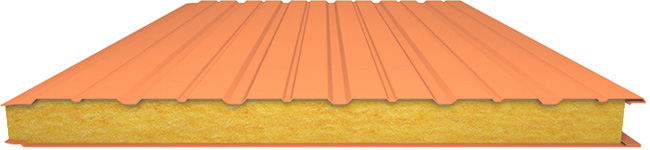

- Mineral Wool for Panel Core

-

※ Actual product may seem different from the image, please contact the sales staff for the details.

※ Actual product may seem different from the image, please contact the sales staff for the details.

-

Byucksan Mineral Wool for panel core uses mineral wool from hot-dip calcium silicate ore, and used as core material of sandwich panel which requires fireproof function with its strong heat resistance that does not burn easily from fire.

- Features

-

- Core material of sandwich panel which requires fireproof function

- General Size

-

Standard Size Related Standard Density

(kg/㎥)Thickness

(mm)Width

(m)Length

(m)90 or higher 72

80

841 2 KS L 9102

KS L 9016※ Please contact the person in charge for the other sizes. (Prohibited to use other than its usage.)

- Properties

-

Thermal Conductivity W/mK Heat Shrinking Temp. (℃) Average Temperature 70℃ 0.044 or lower 600 or higher

- LOOSE WOOL

-

※ Actual product may seem different from the image, please contact the sales staff for the details.

※ Actual product may seem different from the image, please contact the sales staff for the details.

-

Loose Wool packs mineral wool in fibrosis state(granule type), usable to fit to location and size of the working site, and is excellent in heating/sound absorption.

Best product with fiber thickness of around 4㎛, and particle content (500㎛ or more) of 2% or less.

- Features

-

- Fireproof zone

- Raw material of mineral wool sound absorption ceiling system

- Insulation system for semi-wet spray construction method of house ceiling/wall, etc.

- Other parts difficult to construct with mat or board

- General Size and Properties

-

Standard Density (Kg/㎥) Thermal Conductivity W/mK Heat Shrinking Temp. (℃) 70℃ 40~150

(according to bulk density at use)0.044 or lower 650 or higher ※ 상기 물성은 루스울 자체 물성입니다.

- Raw Material Mixing Ratio

-

Usage Loose Wool Cement For insulation 1 0.28 For sound absorption, condensation prevention 1 0.3

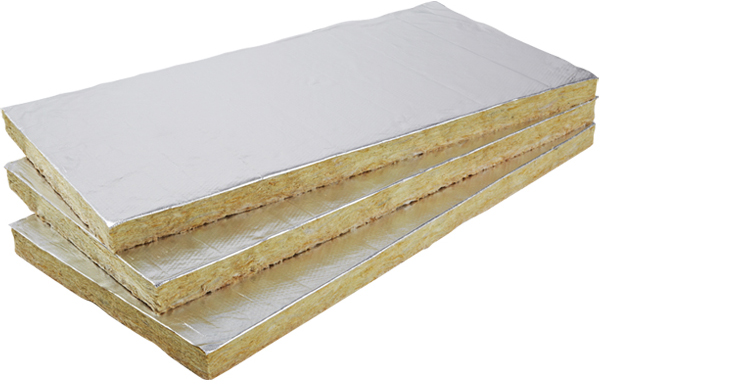

- Heat Insulation Material with attachment

-

※ Actual product may seem different from the image, please contact the sales staff for the details.

※ Actual product may seem different from the image, please contact the sales staff for the details.

-

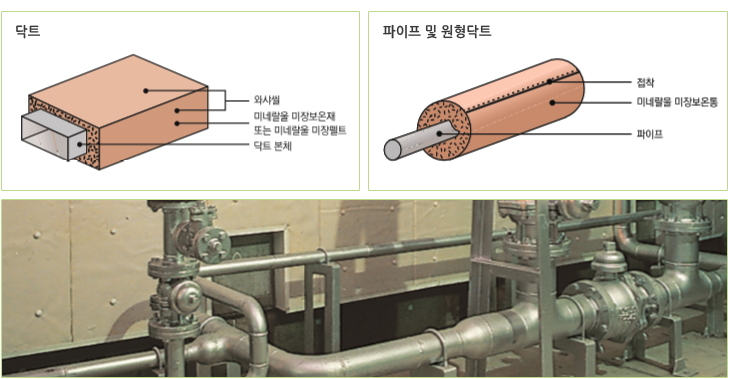

Heating insulation materials for plastering is the product attaching various surface materials to mineral wool, and processed as aiming for fast construction, labor elimination and homogenization.

- Features

-

- Easy construction.

- No additional dampproof or finishing materials required.

- Diverse sizes.

- Economical.

- Application

-

- Construction (heating insulation materials, sound absorption materials, fire resistance materials of wall, ceiling, floor, etc.)

- Facility (heating insulation materials, sound absorption materials of duct, piping, facility, etc.)

- Raw Material

-

Product Name Mineral Wool Board Mineral Wool Felt Mineral Wool Pipe Cover

- Surface Processed Material

-

ALGC Alumi - Glass Cloth ALK Alumi - Kraft ALPY Alumi - PVC Yarn GC Glass Cloth ※ Other surface processed materials are producible by the order.

- SUPER WOOL

-

※ Actual product may seem different from the image, please contact the sales staff for the details.

※ Actual product may seem different from the image, please contact the sales staff for the details.

-

Super Wool is Byucksan’s own product which is officially certified from domestic/foreign certification organizations including Lloyd's Classifications as fireproof insulation system for high-temperature developed for industry and ships. Especially, Super Wool is appropriate for all kinds of insulation facility for industrial facility and ship areas, and fireproof materials of ships and power plants.

- Features

-

- Grade 1 incombustible material of excellent fireproof function with high heat resistance.

- Excellent processability with great flexibility as fiber material.

- Excellent in high-temperature insulation, sound absorption, humidity/weather resistance performance.

- Application

-

- For industrial use

Economic and ideal high-temperature non-flammable insulation system i.e. annealing furnace for non-ferrous metals, heat treating furnace, drying furnace, baking furnace, insulating materials of power plant. - For marine use

Acquired A-Class Bulkhead&Deck cert. by SOLAS (Safety Of Life At Sea) and Non-Combustible Material cert. by IMO Resolutions.

- For industrial use

Ceiling System

Ceiling System Insulation System

Insulation System Interior System

Interior System Exterior System

Exterior System