-

- Byucksan Baritone Panel is convenient to maintain as it is easily wipe in case of surface contamination by dust with low absorptiveness (1.0% or less).

-

- Product Inquiry : (+82) 02-2260-6054

- E-mail : leehwa5855@bsco.co.kr

- Export Inquiry : (+82) 02-2260-6078

- E-mail : esther711@bsco.co.kr

- Design Inquiry : (+82) 02-2260-6118

- E-mail : ykcho@bsco.co.kr

- Introduction

-

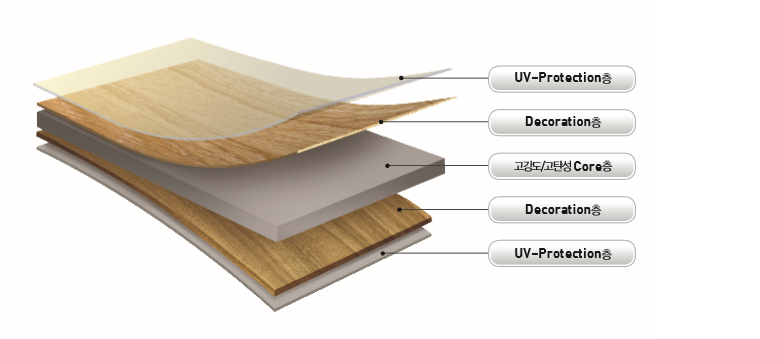

Byucksan Baritone Panel has strong durability and high strength as compressed with high temperature after impregnating tens of natural kraft paper and UV coating paper to resin.

Surface is consists of UV coating layers, so it is strong in breaching, discoloration and UV rays, excellent in weather resistance and easy to maintain compared to other exterior systems.

- Features

-

-

Design

Available to express natural texture,

clear color and various patterns.

-

Durability

Excellent impact resistance, and strong

strength with low absorptiveness

(1.0% or lower).

-

Lightness

Available to reduce structural expenses

of building with the weight less than

13kg/m2.

-

Weather Resistance

No worries for surface damage or

corrosion as exterior system.

-

Stability

Less contraction or expansion after

construction as it is produced

with high temperature press.

-

Convenience

Convenient in surface wash after

construction, and have less surface

contamination.

-

Maximum Size

Available to produce 1,240X4,900mm

in maximum.

-

Eco-Friendliness

Eco-friendly product considering both

nature and humanity.

-

Design

- Construction Cases

-

- Size

-

Thickness (mm) Size (Width x Length) Pattern 8T / 10T 1,240 x 2,450mm Wood 1,240 x 4,900mm

- PATTERN

-

-

BMT 308

BMT 308 -

BMT 352

BMT 352 -

BMT 377

BMT 377 -

BMT 502

BMT 502 -

BMT 616

BMT 616 -

BMT 617

BMT 617 -

BMT 656

BMT 656

-

※ The color of this product may be slightly different from the sample.

| Item | Unit | Specific Standard | Test Method |

|---|---|---|---|

| Density | g/㎤ | 1.40 or higher | KS F 3200 |

| Flexural Strength (Length/Width) | N/㎟ | 100 or higher | KS F 3200 |

| Tensile Strength (Width/Length) | N/㎟(MPa) | 70 or higher | KS M ISO 527-2 |

| Flexural Strength if damp (Length/Width) | N/㎟ | 100 or higher | KS F 3200 |

| Bending Failure Load (Length/Width) | N | 4,000 or higher | KS F 3200 |

| Absorption Rate | % | 1.0 or lower | KS F 3200 |

| Length Change Rate by Absorption | % | 0.2 or lower | KS F 3200 |

| Thickness Expansion Rate by Absorption | % | 0.5 or lower | KS F 3200 |

| Impact Resistance | - | Shall have no crack or flaking on the surface. | KS F 3200 |

| Contamination Resistance (Red Crayon) | - | N/A (Standard Grey, Color Table No.3 or higher) | KS F 3200 |

| Acid Resistance | - | N/A | KS F 3200 |

| Alkali Resistance | - | N/A | KS F 3200 |

| Weather Resistance | Gray scale | Gray scale 4 or higher | ISO 4892-2 (2,000 hours) |

| Formaldehyde Emission | mg/L | Average 0.2 or lower | KS F 3200 |

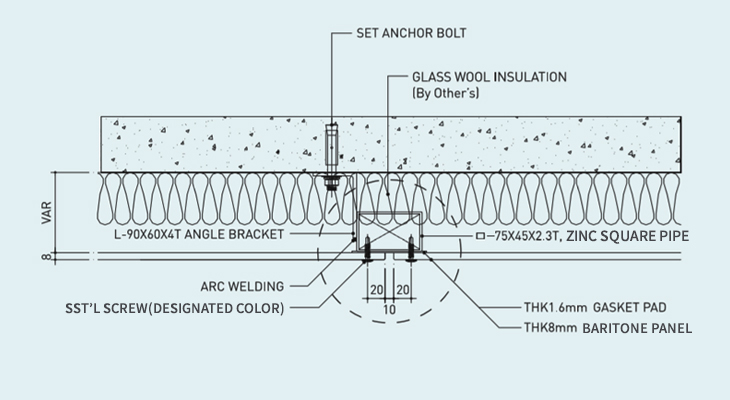

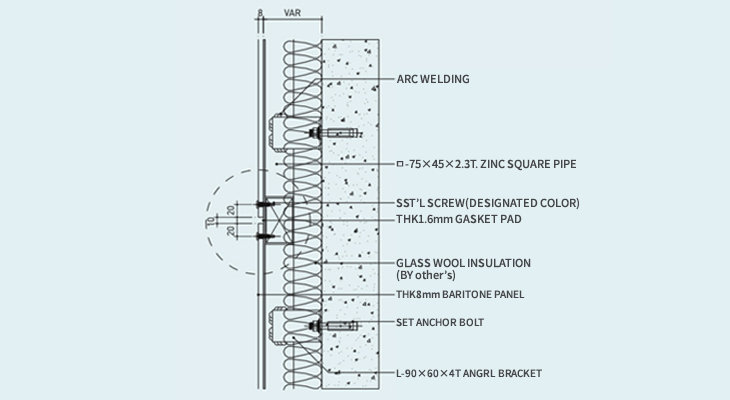

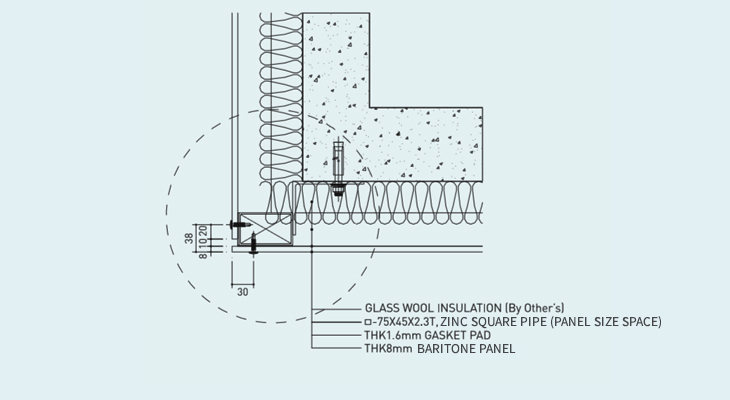

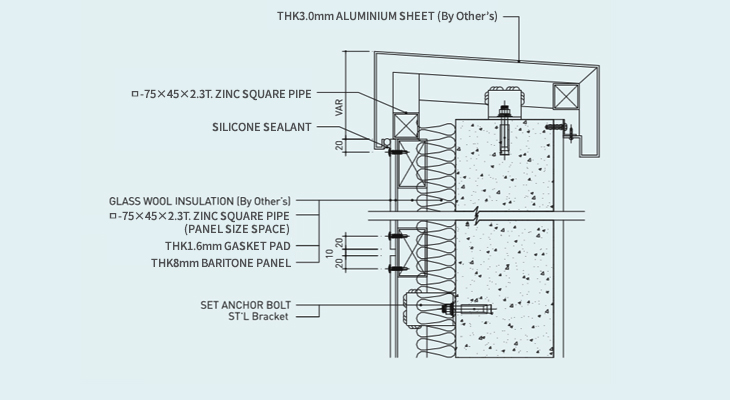

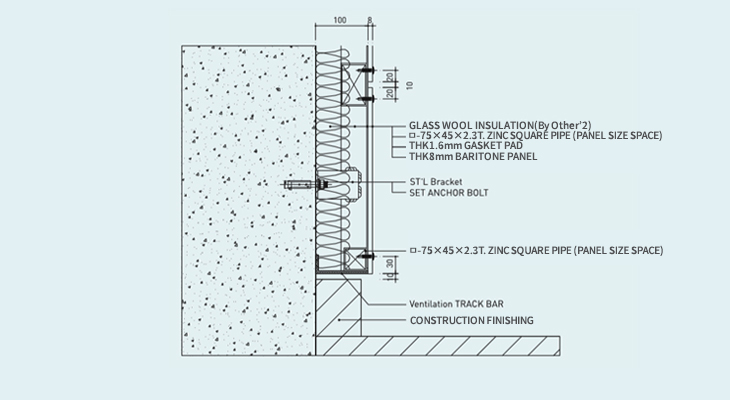

- Detailed Drawing

-

-

Detailed Drawing of Floor Plan

-

Detailed Drawing of Cross Section

-

Detailed Drawing of Corner

-

Detailed Drawing of Parapet

-

Detailed Drawing of Window-1

-

Detailed Drawing of Window-2

-

Detailed Drawing of Window Flat Surface

-

Detailed Drawing of Cross Section for Bottom Finishing

-

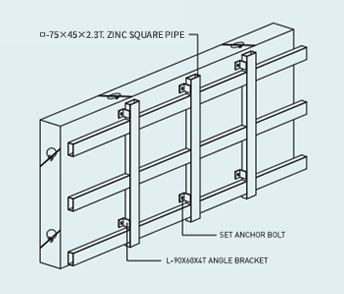

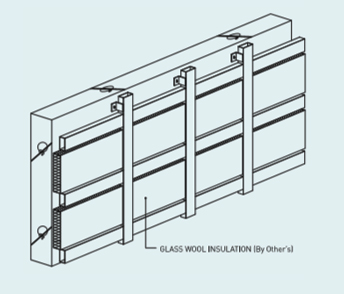

- Panel Installation Procedure

-

-

1. Perform inking line work to install vertical materials

1. Perform inking line work to install vertical materials -

2. Install set anchor and vertical and horizontal pipes of 75x45x2.3T

2. Install set anchor and vertical and horizontal pipes of 75x45x2.3T -

3. Install 75x45x2.3T vertical and horizontal pipes, and then insulating materials

3. Install 75x45x2.3T vertical and horizontal pipes, and then insulating materials -

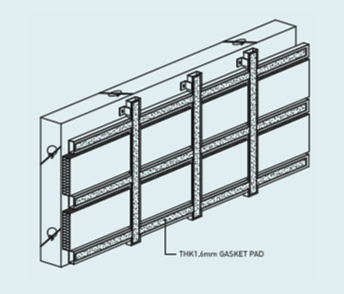

4. Attach gasket pad after installing insulating materials

4. Attach gasket pad after installing insulating materials -

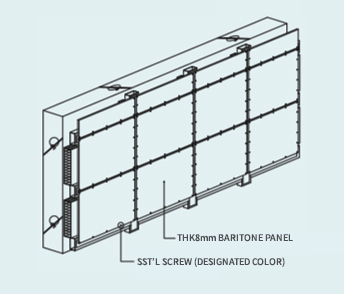

5. Attach gasket pad, then install panel with designated screws as fit to each pipe vertical/horizontal joints.

5. Attach gasket pad, then install panel with designated screws as fit to each pipe vertical/horizontal joints.

-

- Precautions When Installing Panel

-

- 1. When constructing panel with screw, must tighten screw with equal strength to each panel and maintain optimum smoothness.

Gasket pad shall be THK1.6mm, and if using thick pad, smoothness is not even. - 2. Please be careful not to break the screw head if tightening screw with too much power.

- 3. Use SST'L screw for the screw. (Stainless 410/Color TOX)

- 4. Use screw coated with designated color on the head.

- 5. Construct in consideration of characteristics (construction and expansion) of panel while constructing in each season.

- 1. When constructing panel with screw, must tighten screw with equal strength to each panel and maintain optimum smoothness.

Ceiling System

Ceiling System Insulation System

Insulation System Interior System

Interior System Exterior System

Exterior System