-

- Bio Astex which Helps Activation of Body Functionality with Far Infrared Ray Emission!

-

- Product Inquiry : (+82) 02-2260-6234

- E-mail : zeroeat@bsco.co.kr

- Export Inquiry : (+82) 02-2260-6078

- E-mail : esther711@bsco.co.kr

- Design Inquiry : (+82) 02-2260-6118

- E-mail : ykcho@bsco.co.kr

- Introduction

- Byucksan Bio Astex, the noninflammable ceiling system, is made by mixing nonorganic raw materials i.e. gypsum, cement, etc. and far infrared ray emitted ceramic raw materials, and is helping to activate body functionality with bio far infrared ray emission. Also, it is the best seller of the ceiling system which is most commonly used to offices or commercials of general buildings due to its processability and economic feasibility. Create more beautiful ceiling with Byucksan Bio Astex.

- Certificates

-

-iloveimg-resized.jpg)

- Application

-

Ceiling of general building/high-rise building, office, factory, arcade, apartment, hospital, school, hotel, etc.

Ceiling of place where fire and humidity is prohibited i.e. Underground parking lot, subway station, underpass, paper factory, textile factory, electronics factory, etc. - Features

-

-

Non-flammability

Less toxic gas generation from fire

as not burning well in fire as made

of nonorganic materials.

-

Economic Feasibility

Less construction loss like site damage

with high product strength, and

economical with cheap price.

-

Lightness

Suitable for ceiling tiles with low

gravity and impact resistance.

-

Quake proof

Using special lightweight ceiling

subsidiaries, the system could acquire

quake-proof performance and reduce

the damage from earthquakes.

-

Processability

Available to cut and finish with saw or

plane like wood, easy construction with

screw nails, and convenient to coat and

attach paint.

-

Corrosion Resistance

Excellent in corrosion resistance,

no attach of harmful insects i.e. mice,

ants, etc., and never go moldy.

-

Moisture proof

Having less distortion by moisture

absorption compared to gypsum ceiling

tiles makes less sag and keep its

function

-

Sound absorption

Attaching non-woven fabric at the back

side of the tiles, it could provide sound

absorbing performance especially for

classrooms or meeting rooms.

-

Non-flammability

- Size

-

Classification Thickness(mm) Thickness Tolerance(mm) Width x Length(mm) Width, Length Tolerance (mm) Ceiling tile 6 ± 0.4 300 x 600 0, -3 Perforated tile - Packing Unit and Delivery Quantity

-

Packing Unit Delivery Quantity 18 sheets / Box 5Ton : 312 ~390 Box 18Ton : 780 ~ 936 Box

| Specific Gravity | Length Change Rate by Absorption (%) | Bending Failure Load (N) | Moisture Content (%) |

|---|---|---|---|

| 1.5 or less | 0.2 or less | 137.3 or higher | 15 or less |

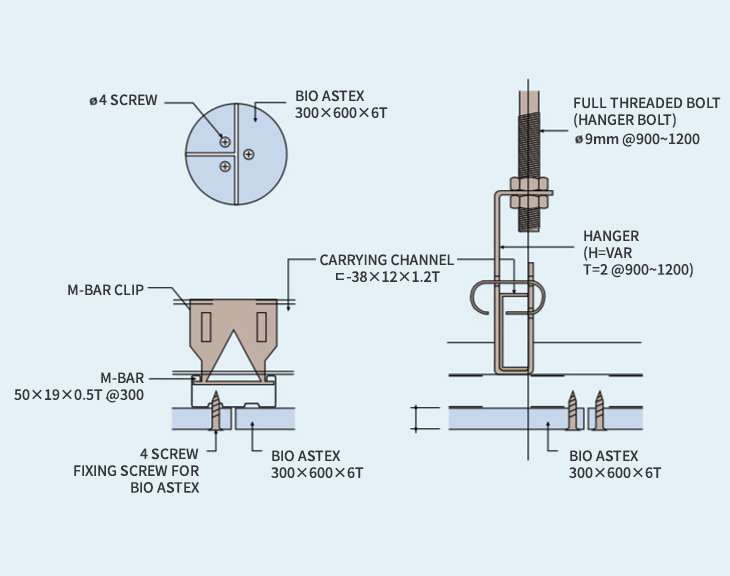

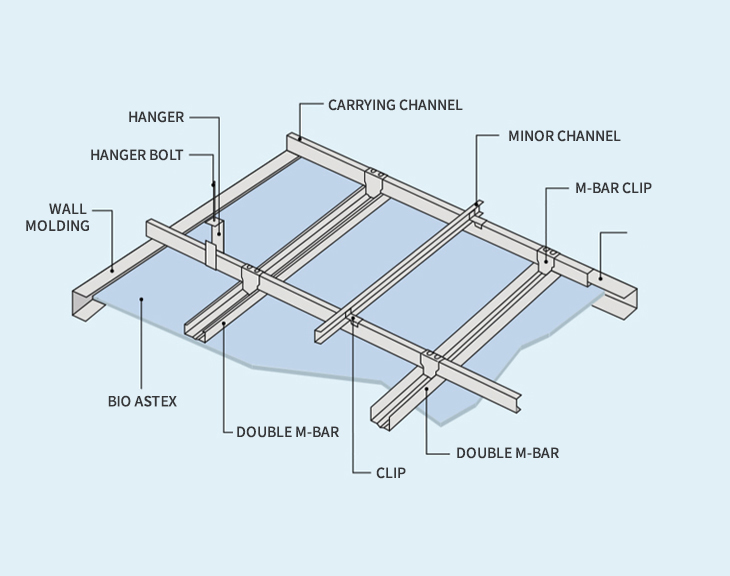

- M-Bar Method

-

-

M-Bar method is the most common and general construction method, and easy to construct with screw nails but strong.

M-Bar method is the most common and general construction method, and easy to construct with screw nails but strong.

Construction order is installing carrying channel, minor channel, M-Bar after setting lighting fixture line.

-

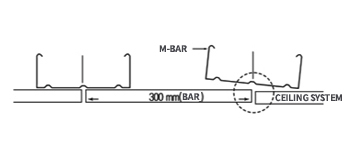

- Detailed Drawing of Cross Section for M-Bar

-

-

- Precautions for Construction

-

-

Make sure to construct M-Bar carefully to not distort like the image above. Please use KS Standard product (50×19×0.5T) to prevent distortion of M-Bar. In case of using non-KS M-Bar, swell might appear with distortion as thickness and width of (45×17×0.3T) Bar is thin and narrow.

Make sure to construct M-Bar carefully to not distort like the image above. Please use KS Standard product (50×19×0.5T) to prevent distortion of M-Bar. In case of using non-KS M-Bar, swell might appear with distortion as thickness and width of (45×17×0.3T) Bar is thin and narrow. -

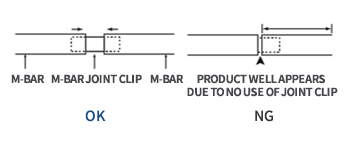

Make sure to use joint clips while joining M-Bar as the image above.

Make sure to use joint clips while joining M-Bar as the image above. -

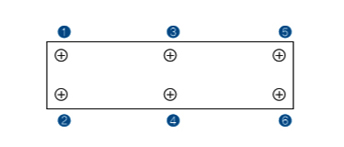

Please follow the order of the image above for screwing screw nails to adhere M-Bar and the product.

Please follow the order of the image above for screwing screw nails to adhere M-Bar and the product. -

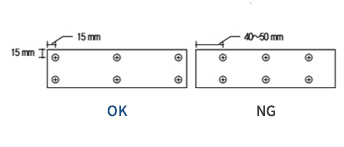

For screw positions of screw nails, install with 15mm space from the corner edge like the image above. If screw positions of screw nails are too apart from the edge, well might appear as end part of the product droops.

For screw positions of screw nails, install with 15mm space from the corner edge like the image above. If screw positions of screw nails are too apart from the edge, well might appear as end part of the product droops. -

Construction Direction

Construction Direction

-

Ceiling System

Ceiling System Insulation System

Insulation System Interior System

Interior System Exterior System

Exterior System